Edit Content

Address

Department of Materials Engineering, Indian Institute of Science Bangalore, Bangalore - 560012, India

Department of Materials Engineering, Indian Institute of Science Bangalore, Bangalore - 560012, India

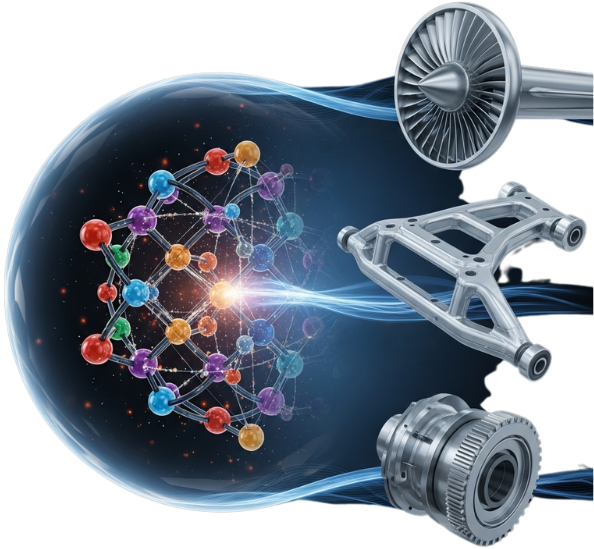

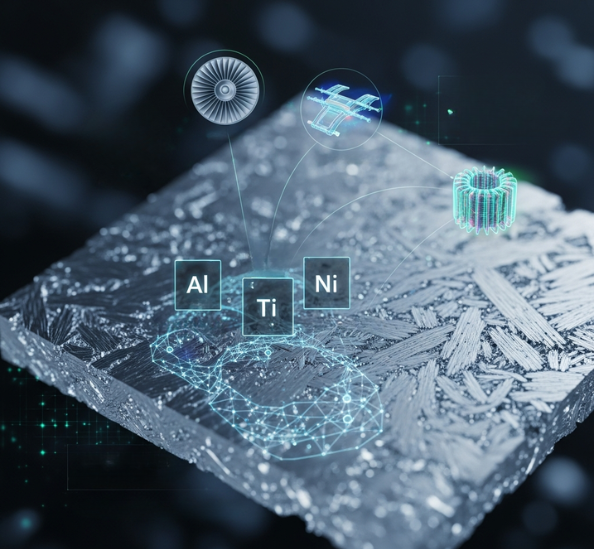

We engineer next-generation materials for aerospace, automotive, and energy applications. By tailoring atomic structure through precise elemental additions, we deliver alloys with superior strength, creep resistance, and lightweight performance.

The Atomic-Scale Engineering of Structural Materials (ASESM) group (formerly Alloy3DLab) is led by Dr. Surendra Kumar Makineni, Assistant Professor in the Department of Materials Engineering at the Indian Institute of Science (IISc) Bangalore. Established around 2020, the lab focuses on atomic-scale manipulation of materials through elemental additions and advanced characterization (e.g., atom probe tomography, TEM) to enhance properties like strength, ductility, creep resistance, and sustainability.

Let’s make something great work together. Contact Us.

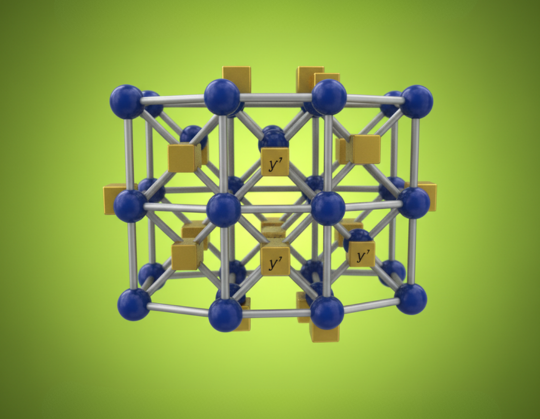

Our research connects atomic-scale structure with macroscopic behavior, revealing the mechanisms that govern strength, stability, and functionality in complex alloys.

Through advanced electron microscopy, 3D atom-probe tomography, and computational modeling, we uncover how nanoscale phenomena dictate material performance and evolution.

From Co-/Ni-superalloys to lightweight Al-/Mg-based systems and high-entropy materials, our studies expand the scientific foundation for next-generation structural and functional materials.

Uncovering the origins of strength, stability, and functionality through controlled alloy synthesis, heat treatment, and advanced microstructural analysis.

Using 3D visualization, electron microscopy, and atom-probe tomography to reveal how nanoscale features evolve and influence mechanical properties.

Transforming complex experimental datasets into high-quality visualizations and open-access resources for journals, conferences, and collaborative projects.

We utilize APT, TEM, and machine-learning frameworks to uncover atomic-scale mechanisms in alloy systems & next-generation materials.

We work with universities, laboratories, and open-access platforms to share data, models, and findings that advance the global materials community.

All our studies adhere to open-data principles, transparent peer-review practices, and reproducible research standards.

01

02

Our digital services empower brands with innovative strategies and solutions for sustainable growth and engagement.

Unique precipitate “signatures” and phase-specific coloration for easy identification in microscopy galleries.

Research summaries, interactive 3D microstructure viewers, and downloadable datasets.

Our proven process combines research, strategy, and creativity to deliver tailored solutions that drive measurable results.

Discover how our clients have achieved success through our innovative solutions and dedicated support.

The team doubled the creep rupture life of our turbine blade alloy while cutting weight by 12 %. Their 3D atom-probe insights were game-changing.

( 40+ Reviews )

Decades of expertise in alloy design, high-temperature materials, and advanced microscopy techniques driving reproducible scientific progress.

Quantitative structure–property correlations supported by hundreds of APT and TEM datasets, enabling statistically robust conclusions.

Partnering with academic institutions, research consortia, and open-data platforms to foster transparent knowledge exchange.

Commitment to mentoring early-career researchers, sharing datasets, and contributing to global materials education through publications and workshops.

Explore the latest trends, strategies, and tools driving digital innovation and helping businesses thrive in a rapidly evolving digital landscape.